|

|

FUTURE

ENERGY eNEWS

|

|

NOVEMBER 2011

|

|

|

|

Dear

Subscriber,

We have a great Fifth International

Conference on Future Energy coming up and look forward to

your continued support. It is important to announce that I have been

appointed the Conference Coordinator and Technical and Publications

Chairperson for the SPESIF-COFE5 event coming up February 29

to March 2, 2012. Many of the deadlines now are much more

flexible (send in your abstract for energy, propulsion or

bioenergetics topic for consideration even up until the end of 2011).

It also means that IRI will consider a group of papers, without a

physical presence requirement. We are planning to offer

Webcasting of the event as well as a Remote Presentation capability

for those who cannot make the trip but would like to present over the

Internet. This is a vital and important energy conference folks. All

of the quality papers from COFE4 that were generously this year are now online. View

ALL of the SPESIF2011 and COFE4 papers and download ANY of them for

FREE (pdf): Physics Procedia -

ScienceDirect (c) Elsevier B.V. Elsevier Science has been

contracted for COFE4 and COFE5 to replace the American Institute of

Physics publisher. We feel that Elsevier is better in many

regards and also most importantly, embraces all of the energy topics

that we entertain.

Looking at our top story, IRI

consulted one of the world's experts in Low Energy Nuclear Reactions

(LENR) to get his opinion of the Rossi development. It

is worthwhile to note that Dr. George Miley has equaled the

Rossi performance and is well known in the field for many years.

The Venture Capital article can

be a resource guide for those doing research. The article looking on

the bright side of solar energy after Solyndra is also very valuable

for predicting future energy trends, as well as the last article on

recharging a battery in ten minutes.

For

those bioenergy fans, who keep asking us for more articles on the

topic, we want to emphasize the significance of the #5 article

that announces, "Cancer Craves Killer Free Radicals". If

ever there was a reason to boost your electronic antioxidants

throughout the day, we believe that this is one of the most

convincing. Furthermore, IRI has developed, under Dr. Jacqueline

Panting's direction, "Therapeutic Electronics Antioxidant

Clothing" (patent pending) which answers the concerned senior

citizen's need for daily free radical protection far exceeding pills

or potions. This is because electrons are antioxidants. See http://www.inventionhome.com/InvPortfolio/Portfolio/TV013678/virtual/TV013678.html for more details of the

solution to the free radical disease and aging threat.

Thomas Valone,

PhD, PE Editor

www.IntegrityResearchInstitute.org

|

|

|

|

|

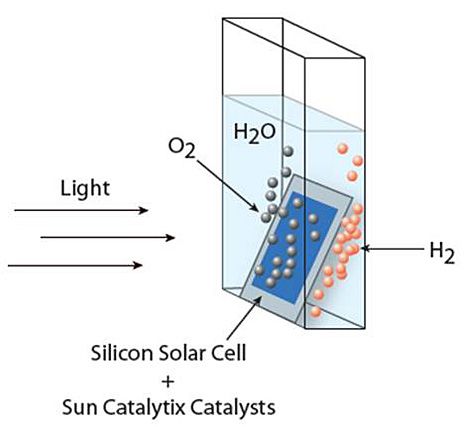

1)

Artificial Photosynthesis to Produce Fuels

|

By Dave

Levitan / November 2011 IEEE Spectrum

http://evworld.com/news.cfm?newsid=25321

|

|

|

Photo: Sun Catalytix

|

If every leaf on the planet can

do it, maybe we can too. Scientists have long tried to mimic

photosynthesis as a way to harness the energy in sunlight

and turn it into a usable fuel, just as plants do. There have been

big technical challenges for just as long, and though scientists are

far from the ultimate goal, two reports published online in the

journal Science yesterday

describe some solutions to the obstacles.

In one

report, a group led by MIT chemistry professor Daniel

Nocera found a new way to use light to split water molecules

into oxygen and hydrogen, which could

then be stored and used as a fuel. Other

groups have had some success with this process before, but there

were always stumbling blocks that would make it hard to scale up or

commercialize, such as extremely acidic or basic conditions,

expensive catalytic materials, or both. However, Nocera's group

managed to get artificial photosynthesis to work using benign

conditions and cheap, abundant materials as catalysts.

Specifically, the team joined a

commercially available triple-junction solar

cell to two catalysts: cobalt-borate for splitting the water

molecule and a nickel-molybdenum-zinc alloy to form the hydrogen gas.

The water-splitting reaction achieved a sunlight-to-fuel conversion

of 4.7 percent in one incarnation of the device and 2.5 percent in

another. The difference between the two was that the more - efficient

device housed the hydrogen-generating alloy on a mesh wired to the

solar cell. The less efficient version was wireless, and the alloy

was instead deposited onto the stainless-steel back of the solar

cell.

It is the wireless possibility,

where the entire device is self-contained, that researchers say is

most exciting. "Because there are no wires, we are not limited

by the size that the light-absorbing material has to be," says

Steven Reece, a research scientist with Sun

Catalytix (a company cofounded by Nocera) who worked on the

discovery. "We can operate on the micro- or even nanoscale...so

you can imagine micro- or nanoparticles, similar to the cells we've

worked with here, dispersed in a solution." The researchers say

they are still deciding what size the final product should

be-anywhere from a small, leaf-sized stand-alone system that might be

able to power an individual home to a much larger system that could

benefit from economies of scale. Whatever size they decide on, the

researchers believe such devices could help provide power in poor

areas that lack consistent sources of electricity.

"As the inputs are light

and water, and the output is fuel, one can certainly see the

applicability of something like that to the developing world,"

says Thomas Jarvi, chief technology officer at Sun Catalytix.

Jarvi says the company expects

to be able to bring the device to the point where a kilogram of

hydrogen could be produced for about US $3. Given that a gallon of

gasoline contains about the same amount of energy as 1 kg of

hydrogen, as long as gas prices stay north of $3 per gallon, this

would make a cost-effective fuel source.

Daniel

Gamelin, a professor of chemistry at the University of Washington

who works on related topics but was not involved with the new study,

says the MIT and Sun Catalytix work represents an "impressive

accomplishment." However, he says, it remains to be seen whether

silicon is really the most desirable material to use, noting that

something less susceptible to degrading by oxygen may be a better

option.

"For these specific

devices, there remain open questions about their long-term

stability," Gamelin says. "And their efficiencies would

still need to be increased substantially to be commercially viable.

But there is obviously potential for improvement on both fronts. In the

bigger scheme, [this research] marks important progress toward the

development of truly practical solar hydrogen technologies."

The

other report, published simultaneously with the hydrogen

producer, demonstrated a different type of advance-a step toward using

sunlight to recycle carbon dioxide. In the natural world, the

sun's energy extracts electrons from a water molecule, which then

reduce CO2 into fuel (in plants, the fuel takes the form

of carbohydrates). University

of Illinois graduate

student Brian Rosen and other scientists were able to invent a device

that electroreduced CO2 to carbon monoxide at a lower

voltage than previously achieved. The high voltages usually required

have been a primary stumbling block in CO2 electroreduction

in the past. Rosen's group brought the voltage down by using a

combination of a silver cathode and an ionic liquid electrolyte that

presumably stabilized the CO2 anion. And according to Rich

Masel, who led the research and is CEO of Dioxide

Materials, a company working on CO2 electroreduction

with the University of Illinois, this piece of the photosynthetic

process could eventually lead to a way to turn captured CO2

into "syngas"-a mixture used in the petrochemical industry

to make gasoline and other fuels.

The experiment "shows that

one can make syngas efficiently from any source of electricity,"

Masel says. However, large-scale versions of the device probably

won't be demonstrated until 2018. "Presently we have

demonstrated the process on the 1-centimeter-squared scale. We need

to go to the million cm2 to make significant amounts of

gasoline."

Work on artificial

photosynthesis has ramped up considerably in recent years. In July

2010, the DOE began funding a Joint

Center for Artificial Photosynthesis to the tune

of $122 million over five years as part of its Energy Innovation Hubs

program; it is led by Caltech professor of chemistry Nate Lewis. The

center, with close to 200 members in universities and national

laboratories across California, aims to build on nature's

photosynthetic design, bridging all the disciplines required, from

chemical engineering to applied physics.

In an interview earlier this

year, Lewis told Spectrum that progress is certainly being

made, but it isn't clear yet if the right combination of catalysts

and light absorbers and everything else that goes into practical

artificial photosynthetic devices has been found.

"We're seeing light in the

tunnel," he said. "We don't know where the end of the

tunnel is. It's a curved tunnel."

|

|

2) PolyPlus Lithium/Water Battery

Could Be "Game Changer"

|

EV World NewsWire, March 3, 2011, http://evworld.com/news.cfm?newsid=25321

Ed. Note: This PolyPlus

invention was also voted one of the "Best 50 Inventions" of

the year in Time magazine. - TV

Batteries made of lithium and

seawater (or just plain tap water for that matter) could be on their

way to a marine market near you.

That's courtesy of a technology made by a 11-year-old company called

PolyPlus and various partnerships, which hails out of Lawrence Berkeley Labs and has

a grant from the Department of Energy's high risk, early-stage ARPA-E

program. At the

annual ARPA-E Summit this week, PolyPlus was highlighted as a

potential game-changer by ARPA-E Director Arun Majumdar, and I got a

chance to sit down with PolyPlus CTO Steven Visco on Monday.

The chemistry

almost sounds like that of science fiction, but Visco told me in an

interview that he thinks the company's water battery could get to

market in two years time, and says the company is just starting the

process of producing a water battery pilot production line now. The

water battery isn't even the end goal for PolyPlus; the company is

developing a non-rechargeable lithium-air and a rechargeable

lithium-air battery, which is the most difficult of the three to

manufacture and for which it received the ARPA-E grant.

Here's how the

water battery works: An encapsulant encloses the lithium,

completely separating it from the water, but still enabling a charge.

That's crucial because lithium and water react rather shockingly

(Visco showed me videos of lithium essentially dissolving in water).

Visco says it

was a Eureka moment when he realized the battery worked, using a

membrane from a third party in Japan and the

company's own three-layer system, and was stable in 2003.

"Cycling lithium and water was absolutely unheard of," and

after that, the company went "dead silent," says Visco, and

turned to filing patent after patent.

A water

battery can achieve awe-inspiring energy densities (the amount of

energy that can be stored in a battery of a given size) of 1,300

wh/kg (for small batches), and potentially 1,500 wh/kg at larger

scale production. For comparison, standard lithium-ion batteries have

closer to 200 wh/kg to 400 wh/kg. That means a water battery can last

a very long time. Picture a battery used for a device on the outside

of a ship, or an underwater unmanned vessel that needs power (hello,

DOD), that can just keep going and going

The water

battery also doesn't have to carry the positive electrode, or the

water, inside it. PolyPlus' water battery has an open system where

the water of the surroundings connects with the lithium. That means

the battery could be more simple and lower cost to produce.

All in

all, Visco thinks the marine battery market could be half a

billion dollars. That could be overambitious, as many of the

applications we discussed are early-stage themselves. But a battery

expert source I talked to about PolyPlus' water battery thought the

device was well on its way and could be a big hit for the company.

The

rechargeable lithium-air battery, for which it received the ARPA-E

grant, could be considerable harder. Though the dream is even bigger:

a battery that one day could make electric vehicles with ranges from

300 to 500 miles. If PolyPlus gets there, it will be at least five

years away, and perhaps two decades before car markers start using

these types of batteries for EVs. It took an innovative car company

like Tesla that long to put standardized lithium-ion batteries into

EVs.

Still, you

have to wonder why PolyPlus hasn't moved into manufacturing before

this. Visco told me the company doesn't want to be just a licensing

company, but wants to be manufacturer and is in the process of

raising funds from VCs and strategic investors right now. When the

funding round are closed, hopefully, the water battery will be on its

way.

RELATED ARTICLES

New Battery Technology Could Provide Large-Scale

Energy Storage for the Grid

Dexter Johnson / Fri, November 25,

2011 IEEE Spectrum

http://spectrum.ieee.org/nanoclast/semiconductors/nanotechnology/new-battery-technology-could-provide-largescale-energy-storage-for-the-grid

I, like many

others, have been following

the work being done by Yi Cui at Stanford University

in improving battery technology.

Cui's work has

often aimed at improving Li-ion battery technology, much in the same

way researchers

at Northwestern University recently have done in getting a

silicon-graphene sandwich to act as a more effective anode.

But in his most

recent research he has abandoned the use of lithium ions and

replaced them with either sodium or potassium ions for his new

battery technology.

The result is

a battery that Cui and his colleagues claim is able to retain 83% of

its charge after 40,000 cycles, which compares more than favorably to

Li-ion batteries of 1,000 cycles.

The

researchers have been able to develop a cathode material that they

can essentially mix in a flask by combining iron with cyanide and

then replacing half of the iron with copper then making crystalline

nanoparticles from the compound.

There is a

weight penalty with this battery technology, which means that it will

not be likely powering any laptops or electric vehicles. However, it

may be the perfect fit for large-scale energy storage on the

electrical grid.

"At a

rate of several cycles per day, this electrode would have a good 30

years of useful life on the electrical grid," said Colin

Wessells, a graduate student in materials science and engineering who

is the lead author of a paper describing the research, published this

week in Nature

Communications.

"That is

a breakthrough in performance - a battery that will keep running for

tens of thousands of cycles and never fail," said Cui, who in

this case is Wessell's adviser and a coauthor of the paper.

But all is not

resolved as of yet. While the researchers have developed this 'new

chemistry' for the battery, they only have the high-power cathode at

this point, so they still need to develop an anode.

Nonetheless

the researchers are confident they will develop a material for the

anode. If they manage to get that sorted, they may have developed an

economical battery for storing energy from solar and wind power so as

to avoid sharp drop offs in electricity in the grid.

ADDICTED TO POWER: USING

TECHNOLOGY TO BUILD A BETTER BATTERY

Ben Bajarin

TIME.com

http://techland.time.com/2011/11/21/addicted-to-power-using-technology-to-build-better-batteries/

When walking

through an airport, have you ever tried to find an outlet for your

computer or to charge your phone only to realize that every last

outlet is being used? I have this experience often since I travel for

business quite a bit. The same is true of my house. There never seems

to be enough plugs to charge all my gadgets. Then again, I have too

many gadgets.

Whenever I

have this experience, I am reminded of the sad state of battery

technology for our mobile devices. The constant need to charge our gadgets

is about as irritating to me as having to put gas in my car.

Charging, like having to get gas, is an irritating task. It makes me

feel like somehow my freedom is restricted-and in a way, it is.

(MORE: TV

Needs to Be Reinvented)

On Twitter

this week, Bill

Gates put out a call for the creation of new and better

renewable energy sources. He also shared

a stat I thought was interesting: All the batteries on Earth

store just 10 minutes worth of world electricity needs.

Unfortunately,

battery technology is a limited science. We don't have the luxury of

having our battery technology follow the pace of innovation or

technological advancements like we do with other technologies. This

is going to be a limiting factor for the foreseeable future, too.

Technology innovation

is not bad, of course. It's good and encouraging. But having said

that, our issues with short battery life are partially our fault. The

market's desire for thinner PCs, smartphones, and tablets with

brighter screens and faster processors all require making tradeoffs

that impact battery life. Innovation isn't bad, as I said, but the

reality is that our desire for innovative electronics is hampered by

the limited science of our current battery technology.

So what can be

done about it? Is there hope, or are we doomed to need to recharge

all our gadgets on a daily basis? There are several things happening

that I want to highlight, along with emphasizing that more still

needs to be done.

The first is

advancements in microprocessors. The brains that power our

electronics have come a long way. Every company making

microprocessors for PCs, tablets, smartphones and any other mobile

technology we dream up is working on creating more power efficient

processors. The goal is to create processors that are still powerful,

but don't require more power themselves, which drains battery life.

This is important because as we demand more processing power in our

devices to do things like run our apps, play media-rich games and

browse multimedia-filled web pages, we need faster CPUs.

(MORE: Do

Windows 8 Tablets Stand a Chance?)

If you follow

the technology industry, you're familiar with a term called "Moore's

Law." One of Intel's founders, Gordon E. Moore stated that the

number of transistors which could be placed on a single chip would

double every 18 months. Note that this does not mean processing

performance necessarily doubles every 18 months-only the number of

transistors.

There is a key

observation, however, for Moore's

Law and mobile devices. Moore's Law not only makes it possible to

double transistors every 18 months, but it also paves the way for

chips to become smaller and, in turn, require less power. This is why

companies like Intel and AMD are racing to create new processor

architectures on an annual cadence. With each new generation, we can

have roughly the same computing power, but with smaller processors

which require less power. Key advancements by all players in the

silicon space are happening in a way that, over time, will see

significant computing power that requires less battery power to

achieve.

The second

thing that is happening is experimentation around battery technology

itself. As I stated previously, lithium-ion battery technology is a

limited science. People have been trying to achieve breakthroughs

with this technology for some time with little success. However,

Northwestern University recently

released a report and white paper stating that researchers there

had created created an electrode for lithium-ion batteries that

allows the batteries to hold a charge up to 10 times greater than

current technology and can charge 10 times faster than current

batteries.

As with all

early research, it takes time and money to see if these new

technologies could be sustained and produced commercially for the

mass market. This new research out of Northwestern is encouraging,

and I'm hearing of work in other technology labs that are also trying

to create breakthroughs with lithium-ion batteries.

Unfortunately,

making technological advancements in microprocessors, lithium-ion

batteries, and perhaps some new energy source simply takes time. The

important thing is that key work is being done to address our battery

life issues with our devices. So for the foreseeable future we will

still have to fight for outlets at the airport and charge our

smartphones at least once each day. But that's the reality of today;

hopefully not the reality of tomorrow.

(MORE: In

the Future, We Will All Talk to Computers)

Ben Bajarin is

the Director of Consumer Technology Analysis and Research at Creative

Strategies, Inc, a technology industry analysis and

market intelligence firm located in Silicon

Valley.

|

|

3)Advance Could Challenge China's

Solar Dominance

|

Technology

Review, November 21, 2011 By Kevin Bullis

http://www.technologyreview.com/energy/39157/?nlid=nlenrg&nld=2011-11-21

Chinese solar-panel manufacturers dominate the

industry, but a new way of making an exotic type of crystalline

silicon might benefit solar companies outside of China that have

designs that take advantage of the material.

GT Advanced Technologies,

one of world's biggest suppliers of furnaces for turning silicon into

large crystalline cubes that can then be sliced to make

wafers for solar cells, recently announced two advanced technologies

for making crystalline silicon. The new approaches significantly

lower the cost of making high-end crystalline silicon for highly efficient

solar cells.

The first technology, which GT calls Monocast,

can be applied as a retrofit to existing furnaces, making it possible

to produce monocrystalline silicon using the same equipment now used

to make lower quality multicrystalline silicon. It will be available

early next year. Several other

manufacturers are developing similar technology.

It's the second technology, which the company

calls HiCz, that could have a bigger long-term impact. It cuts the

cost of making a type of monocrystalline silicon that is leavened

with trace amounts of phosphorous, which further boosts a panel's

efficiency. This type of silicon is currently used in only 10 percent

of solar panels because of its high cost, but could gain a bigger

share of the market as a result of the cost savings (up to 40

percent) from GT's technology. The technology will be available

next year.

A standard solar panel, made of multicrystalline

silicon, might generate 230 watts in full sunlight. A panel the same

size made of monocrystalline silicon could generate 245 watts. But

phosphorous-doped monocrystalline silicon (also called n-type

monocrystalline) enables a type of solar panel that generates 320

watts, a huge leap in performance.

Most Chinese solar manufacturers have focused on

multicrystalline silicon solar panels. Companies such as U.S.-based

Sunpower have focused on the advanced monocrystalline panels, and

have designed cells to exploit its properties. Such companies will

benefit as the HiCz technique developed by GT Advanced Technologies

becomes more common.

"There's a potential shift in the

market," says Vikram Singh, general manager for the photovoltaic

division at GT Advanced Technologies. He says some western companies

could become more competitive because they have technologies to take

advantage of the materials.

Several other companies are developing

technologies similar to Monocast, including solar-panel makers in China,

such as Suntech and the Dutch equipment maker ALD.

The HiCz technology can be considered the next

step on the way to higher-efficiency solar cells. It can be used to

make monocrystalline silicon, even the phosphorous-doped type, for

about the same cost as the Monocast technology. HiCz could allow a

leap from cells that convert 16 to 18 percent of the energy in

sunlight into electricity to ones that can convert 22 to 24 percent,

thus decreasing the cost per watt of solar power. But it can't be

retrofitted to existing equipment, which could slow its adoption.

The conventional way to make monocrystalline

silicon is to introduce a seed crystal into a pool of molten silicon

and slowly draw it out-as you do, it forms a large tube-shaped chunk

of silicon called a boule, in which all of the atoms are lined up in

the same orientation. This is usually done in a batch process, but

the HiCz process makes it possible to continuously feed in raw

silicon to the melt, along with whatever trace elements are needed to

give it the desired electronic properties. The continuous process is

more productive, which means fewer machines are needed, reducing

costs. It also produces high yields when introducing materials

including trace elements such as gallium and phosphorous. GT

estimates the process can reduce the costs of making monocrystalline

solar by between 20 and 40 percent.

RELATED ARTICLE

US Eyes Deal Outside WTO on

China's Green Subsidies - Solar Panels

Bridges Weekly Trade News Digest

2 November 2011 Vol. 15 No. 37 , Inter Centre for Trade and Sustainable

Development, http://ictsd.org/i/news/bridgesweekly/117357/

The US will take advantage of

several high-level meetings in Asia this month to address barriers to

trade in environmental goods and services (EGS). Tensions between

Washington and Beijing have been high in recent months as US

lawmakers and manufacturers have increasingly sought action against

China's green subsidies.

US Trade Representative (USTR)

Ron Kirk told a business group last week that he would push for a

voluntary tariff binding of five percent on a "basket of

issues" relating to green technologies, facilitating trade

between a number of nations competing for a stake in the new energy

sector.

The US will raise the issue with

China and other Asia-Pacific Economic Cooperation (APEC) partners at

a meeting of the regional body in Honolulu next week. The US will

also have the opportunity to discuss the arrangement one-on-one with

China shortly after the APEC summit at the US-China Joint Commission

on Commerce and Trade, and in meetings on the sidelines of APEC with

eight additional members that are involved in the ongoing

Trans-Pacific Partnership talks.

While Kirk says he has the support of Australia,

New Zealand and others, a trade diplomat told Reuters that China

prefers to leave the matter to the WTO. Keeping the negotiations in

Geneva would allow China to cut a tariff deal in exchange for trade

concessions from other WTO members, while also preventing the deal

from moving forward on a voluntary basis. If the tariff bindings are

to become WTO-enforceable, observers suggest that EGS negotiations

could become far more complex.

|

|

4) Small Nukes Get

Boost

|

By Kevin

Bullis http://www.technologyreview.com/energy/38897/?nlid=nlenrg&nld=2011-10-24

The large

engineering and construction firm Fluor has taken a majority stake in

NuScale Power, a startup that has been developing small, modular

nuclear reactors. The investment effectively rescues NuScale, which

had been near financial collapse after its biggest investor was

indicted by the U.S. Securities and Exchange Commission for violating

regulations.

The deal with

Fluor will allow NuScale to continue its efforts to license its power

plant design with the U.S. Nuclear Regulatory Commission, with the

goal of having the first one up and running by 2020. Fluor's

engineers will help with the certification work, and the company

eventually plans to engineer and build NuScale's power plants.

The investment

by Fluor is a vote of confidence in small modular nuclear reactors.

These reactors generate 300 megawatts or less, about a third of what

conventional nuclear reactors generate, and are designed to be safer

and easier to manufacture. The technology has been gaining attention

in recent years as high costs and safety concerns, such as those

kindled by the nuclear accident at Fukushima, have hurt the prospects

of large, conventional nuclear power plants. At the same time,

organizations such as the International Atomic Energy Agency are

anticipating a large market for small nuclear reactors in poor

countries and in rural areas that don't have the infrastructure or

demand to accommodate conventional large reactors.

Other major

engineering and construction companies in the nuclear industry have

recently shown support for small modular reactors, including Bechtel

and Babcock & Wilcox, which this summer

announced a partnership with the Tennessee Valley Authority to

work toward building six of Babcock and Wilcox's small mPower

reactors. Worldwide, dozens of designs being developed, including

efforts in Japan, Korea, China, Russia, and Argentina. U.S.

Energy Secretary Steven Chu has made development and licensing of

small modular reactors a focus for the U.S.Dept of Energy

The NuScale

reactor design is based on technology developed by the DOE and Oregon

State University, which was involved in the design and certification

of the new Westinghouse AP1000 power plants that are being built now

in China and at two locations in the United States. The reactor is a

type of light water reactor, one of the most common types of reactors

in use today. NuScale has completed a detailed preliminary design,

and intends to submit a design certification application to the NRC

next year.

NuScale's

reactors are designed to generate 40 megawatts each, compared to over

1,000 megawatts for conventional reactors. They can be linked

together on site to generate larger amounts of electricity.

Traditionally, nuclear power plants have been built large to take

advantage of economies of scale. But the large size of the projects

leads to long construction times, and delays and cost overruns are

common, heightening the risk for investors and increasing financing

costs.

Smaller

reactors, which can be built in factories rather than assembled on

site, could be faster to build, lowering financing costs. The designs

can also be simpler, and thus cheaper than conventional nuclear power

plants, since the smaller reactors require lower pressures, for

example, and their small size makes it practical to combine multiple

elements into one containment vessel. Some experts have calculated

that costs per megawatt could be comparable to large nuclear

reactors, but no one really knows because no small, modular

commercial nuclear power plants have been built yet.

Even if costs per megawatt

prove higher than with conventional plants, their small size might

make them attractive in areas that lack the power lines and other

infrastructure needed to distribute power from a large reactor, and

that may not immediately have demand for the full power output of a

large reactor. The modular design could allow utilities to gradually

add more reactors as demand increases. Several rural electric cooperatives

in the United States have expressed interest in using NuScale's small

nuclear reactors to replace aging coal plants-the small size of the

plants would eliminate the need to upgrade existing transmission

lines. Critics of small nuclear reactors, such as the Union of

Concerned Scientists, say that large numbers of small reactors could

be more difficult to manage during an accident, and could pose

greater risk of nuclear materials falling into the hands of

terrorists or rogue states.

|

|

5) Red Laser and

Green Tea Attack Alzheimer's

|

New Scientist, November 2011

http://www.newscientist.com/article/mg21228374.600

IT MAY sound like a strange brew,

but green tea and red light could provide a novel treatment for

Alzheimer's disease. Together, the two can destroy the rogue

"plaques" that crowd the brains of people with the disease.

The light makes it easier for the green-tea extract to get to work on

the plaques.

|

|

|

Brain showing Alzheimer's disease. Photo

courtesy Science Daily

|

Andrei Sommer at the University

of Ulm in Germany, and colleagues, have previously used red light

with a wavelength of 670 nanometres to transport cancer drugs into

cells. The laser light pushes water out of the cells and when the

laser is switched off, the cells "suck in" water and any

other molecules, including drugs, from their surroundings.

Now, Sommer's team have found

that the same technique can be used to destroy the beta-amyloid

plaques in Alzheimer's. These plaques consist of abnormally folded peptides,

and are thought to disrupt communication between nerve cells, leading

to loss of memory and other symptoms.

The team bathed brain cells

containing beta-amyloid in epigallocatechin gallate (EGCG) - a

green-tea extract known to have beta-amyloid inhibiting properties -

at the same time as stimulating the cells with red light.

Beta-amyloid in the cells reduced by around 60 per cent. Shining the

laser light alone onto cells reduced beta-amyloid by around 20 per

cent (Photomedicine and Laser Surgery, DOI: 10.1089/pho.2011.3073).

It can be difficult getting

drugs into the brain, but animal experiments show that the green-tea

extract can penetrate the so-called blood-brain barrier when given

orally together with red light. The light, which can penetrate tissue

and bone, stimulates cell mitochondria to kick-start a process that

increases the barrier's permeability, says Sommer.

There is no reason why other

drugs that attack beta-amyloid could not be delivered to the brain in

the same way, he adds.

"This important research

could form the basis of a potential treatment for Alzheimer's, with

or without complementary drug treatment," says Mario Trelles,

medical director of the Vilafortuny Medical Institute in Cambrils,

Spain.

"The technique described could

help to regulate and even stop the appearance of this disease,"

he adds.

back to table of contents

|

About

Integrity Research Institute

Future Energy eNews is

provided as a public service from Integrity Research Institute, a

Non-Profit dedicated to educating the public on eco-friendly

emerging energy technologies.

FREE copy of the 30 minute DVD

"Progress in Future Energy" is available by sending an

email with "Free DVD" in subject and mailing

address in body.

Your generous support is welcome by making a tax

deductible donation on our secure website

|

|

|

|

|

Save 10%

|

On all purchases from IRI by becoming a member and a free gift when you join and you save 10% on

all conference and workshop fees as well. You will receive

a quarterly mailing with the latest information on eco-friendly

emerging energy technologies. All 2011 IRI members will receive free

copies of Energy magazines and the latest emerging energy technologies

reports.

|

|

|

|

|

|