|

|

|

Dear

Jacqueline,

Beginning the

New Year with resolutions, we at IRI are planning for our next level

of public service so that we can devote full time to this vitally

important cause of clean energy. IRI is hereby issuing a Call

for Papers for

our next joint Conference on

Future Energy (COFE),

along with several other forums under the auspices of the Natural

Philosophy Alliance, to be held July 11-13, 2013 at the

University of Maryland. As many of you know, we are the only

organization in the US that since 1999 has successfully diagnosed,

educated the public and advocated future

energy innovations

that can truly be called "breakthroughs." IRI wants to

continue this critical service at a more expanded scale of operation

in 2013 so any suggestions, endowments or referrals will be

gratefully accepted. By comparison, I attended "Energy

Innovation 2013" sponsored by the "Breakthrough

Institute" (www.itif.org)

in downtown DC with several panels of speakers, none of whom

represented real innovation nor any breakthroughs, except Kevin

Bullis, the Senior Editor for Energy of MIT's Technology

Review (see

his articles below). I met with him afterwards and gave him a review

copy of my book, Zero Point

Energy: The Fuel of the Future, since as I pointed out,

this emerging energy technology has not appeared in his magazine at

all but it has been featured at many conferences. At Energy

Innovation 2013, there was talk of "zero carbon" emissions

but no one had any idea of how to achieve such a lofty goal but we do

with the IRI white

paper on a national energy plan! Another example of a

political energy overture is the upcoming "Symposium on

Energy in the 21st Century" (April 12, 2013) with

the theme "A Future Using Net Zero Energy" that

seems confusing unless we go back to a Stone Age. Acknowledgement is

given for a technological hopeful from NREL who will be a symposium

speaker, Senior

Engineer Jerry Davis.

Our first FE

eNews story of 2013 is an example of a real breakthrough from Science

magazine with

lots of Supplementary

material online. Using a heretofore unknown principle of a

negative "Gibbs free-energy change of absorbed water"

during an expansion and contraction cycle, a polymer married to a

piezoelectric strip generates up to 1 volt and a fraction of a

nanowatt by simply absorbing water thus converting chemical potential

energy in water gradients to mechanical work!

The second

story is an exciting demonstration

from Finland of

a new light-trapping surface for photovoltaic (PV) surfaces losing

only 8% to transmission instead of the usual 46% from anti-reflective

coatings thus significantly improving efficiency. The third story

from Nature follows

this theme of innovations in solar panels with a sticky panel for any

surface that is lightweight and flexible.

A fourth

article summarizes the results of the US DRIVE (Driving Research and Innovation

for Vehicle Efficiency) government

program of the DOE. The National Academy of Sciences is

critical of replacing petroleum but interestingly, Amory Lovins from www.rmi.org has

the final say with his usually succinct assessment that I was

privileged to receive as a member of a global energy news group which

is optimistic "with RMI's help".

Our last story

is an inspiration for electric car owners since the future seems to

be with lithium-sulfide batteries that are projected by Lawrence

Berkley labs to achieve double the storage capacity of current

lithium-ion batteries which has interested the

ARPA-E program as

wel

Sincerely,

Thomas

Valone, PhD, PE.

Editor

|

|

|

QUICK LINKS

|

|

LIKE US ON FACEBOOK AND GET

10% OFF ANY ITEM IN OUR CATALOG!

|

|

|

|

1) Free Energy: Polymer Generator Driven by

Water

|

9:00 10 January 2013 by Jacob Aron- New Scientist

http://www.newscientist.com/article/dn23066-muscle-mimic-pulls-electricity-from-wet-surface.html

Electricity

has been squeezed from a damp surface for the first time, thanks to a

polymer film that curls up and moves - a bit like an artificial

muscle - when exposed to moisture. The film could be used to run small,

wearable devices on nothing but sweat, or in remote locations where

conventional electricity sources aren't available.

See Video Click here

When a dry

polymer absorbs water, its molecular structure changes. This can, in

principle, be converted into larger-scale movement, and in turn

electricity. But previous attempts at creating a material powered by

a moisture gradient - the difference in chemical potential energy

between a wet region and a dry region - failed to produce a useful

level of force.

These

unsuccessful tries used a polymer called polypyrrole. Now Robert Langer and colleagues at

the Massachusetts Institute of Technology have turned to the material

again, embedding chains of it within another material, polyol-borate.

This more complex arrangement mimics structures found in muscles as

well as in plant tissues that bend in response to changes in

humidity.

Flipping film

The result

looks like an ordinary piece of thin black plastic, but when placed

on a wet surface, something extraordinary happens. As the material

absorbs water, its end curls away from the surface and the film

becomes unstable, so it flips over. The ends have now dried out, so

they are ready to absorb more water, and the whole process repeats

itself. This continuous flipping motion lets the film travel across a

suitably moist surface unaided.

Langer

found that a 0.03-millimetre-thick strip, weighing roughly 25

milligrams, could curl up and lift a load 380 times its mass to a

height of 2 millimetres. It was also able to move sideways when

carrying a load about 10 times its mass.

To extract

energy from this effect, Langer's team added a layer of piezoelectric

material - one which produces electricity when squeezed. When

this enhanced film, weighing about 100 milligrams, flipped over, it

generated an output of 5.6 nanowatts - enough to power a microchip in

sleep mode.

Electricity from sweat

Though the

output is small, it is proof that electricity can be extracted from a

water gradient. "To the extent of our knowledge, we are the

first to utilise a water gradient, without a pressure gradient, to

generate electricity," says Langer.

Large-scale

energy harvesting is unlikely as the size of the device needed would

be impractical, but it could be used to power small devices such as

environmental monitoring systems in remote locations. "It will

be interesting for applications where the amount of energy needed may

be low but where access to energy may be difficult," says Peter Fratzl at the Max-Planck Institute

of Colloids and Interfaces in Potsdam, Germany, who was not involved

in the work.

Another

application, Langer suggests, would be to place the film inside the

clothing of joggers or athletes. The evaporation of sweat could

generate enough electricity to power sensors monitoring blood

pressure and heart rate.

Journal

reference: Science, DOI

10.1126/science.1230262

back to table of

contents

|

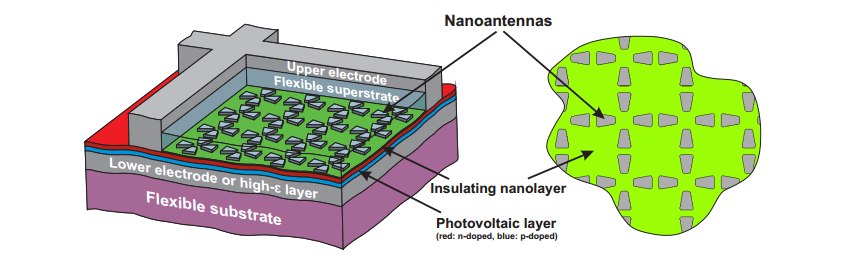

2) How Light-Tapping Surfaces Will Boost Solar

Cells Efficiency

|

|

MIT Technology

Review, January 2013

http://www.technologyreview.com/view/510016/how-light-trapping-surfaces-will-boost-solar-cell-efficiency/?utm_campaign=newsletters&utm_source=newsletter-weekly-energy&utm_medium=email&utm_content=20130121

Improving the efficiency of photovoltaic cells is

one of the great challenges for renewable energy science. In

the lab, the best cells can convert almost half the sunlight hitting

them into electricity (44 per cent) although for the figure

commercial cells is less than half that.

One way to improve matters is to minimise the

amount of light reflected from the cell or transmitted through it,

since this energy is clearly lost. The conventional approach is

to use an anti-reflection coating which can be optimised to minimise

reflections particularly at the cell's optimal frequencies.

But there's a problem. While these coatings are

good at preventing reflections, they cannot stop light being

transmitted. And for the next generation of thin film solar

cells, this is a particular problem. In some cases, almost half the

light passes straight through.

So the most recent research is focused on a

different approach-capturing incoming light and trapping it against

the surface. This prevents both reflection and transmission and

so has the potential to significantly increase the efficiency of thin

film solar cells. The question, of course, is how best to do this in

a way that is commercially viable. Today, Constantin Simovski

at Aalto University in Finland and a few pals reveal their design for

a new light-trapping structure. Their idea is to cover a cell with a

regular array of silver nanoantennas that convert ordinary incoming

waves into more exotic ones that propagate through the photovoltaic

slab itself.

The

work is a theoretical study and simulation of how good these

nanoantennas can be and the conclusions are promising. "We

demonstrate that [the nanoantenna array can] increase significantly

the overall spectral efficiency of solar cells with a very small

thickness." they say.

The

simulations produce some interesting numbers. Simovski and co

calculate that an ordinary anti-reflection coating about 7 per cent

of the light is lost due to reflection while 46 per cent is lost to

transmission.

By contrast, their light-trapping

surface loses 20 per cent to reflection but only 8 per cent to

transmission. The extra surface itself absorbs a further 6 per cent.

That's significantly better but there's also the important question

of fabrication costs.

Simovski and co say that new

fabrication techniques for printing a nanoantenna array on a thin

film mean it could be done at low cost. Whether this can be done on

the required scale at a price that is cost-effective, remains to be

seen.

Nevertheless, light trapping

surfaces look a promising way to increase the efficiency of thin film

solar cells-provided somebody can work out how to make them cheaply

enough.

Ref: arxiv.org/abs/1301.3290:

Enhanced Efficiency of Light-Trapping Nanoantenna Arrays for

Thin Film Solar Cells

back

to table of contents

|

3) Flexible

Solar Cells that Stick to Any Surface

|

Kevin Bullis, Technology

Review, January 2013

http://www.technologyreview.com/news/508946/flexible-solar-cells-can-stick-to-just-about-any-surface/?utm_campaign=newsletters&utm_source=newsletter-weekly-energy&utm_medium=email&utm_content=20121224

Solar panels are

typically heavy, which makes them expensive to install, and rigid,

which limits where they can be used. In the current issue of Nature Scientific Reports, researchers

describe a novel, potentially cheap way to make solar cells that are

both lightweight and flexible.

|

|

|

Solar Cell affixed to a Business Card

|

The technique is meant to work with thin-film solar

cells. The active part of thin-film cells-the part that gathers

sunlight and generates electricity-is thin enough to be flexible, but

the cells usually have to be manufactured on rigid materials such as

glass to achieve the highest quality.

Researchers led by Xiaolin Zheng,

a professor of mechanical engineering at Stanford University,

demonstrated a way to transfer the active materials of the solar cell

from a rigid substrate onto another surface, such as a sheet of paper

or plastic, the roof of a car, or the back of a smartphone. As with

other solar cells, wires would then be connected to deliver power,

but flexible solar cells could be used on curved surfaces, and,

because they're lightweight, they would be easier to install than

conventional panels.

Although Zheng has

demonstrated that the process can transfer solar cells even to cheap

surfaces such as paper, in practical applications, the materials used

would be limited by the need to protect the cells from the elements.

These aren't the first flexible solar panels. Several

companies already manufacture them (see "A Solar Startup that

Isn't Afraid of Solyndra's Ghost" and "Solar Shingles See

the Light of Day"). But Zheng says prior approaches

to making flexible solar cells have drawbacks. Manufacturers often

modify processing steps to accommodate flexible substrate materials

that can't tolerate high temperatures or certain chemicals, but this

can reduce the performance of the resulting solar cell. And

manufacturers have typically used costly flexible substrate

materials, such as foils with extremely uniform surfaces, in order to

produce high-quality thin films.

The trick to peeling

thin-film silicon away from a solid substrate of silicon dioxide

involves depositing a layer of nickel on top of an underlying wafer.

After the cell is finished, it's immersed in room-temperature water.

The water interacts with the nickel and silicon dioxide, causing the

solar cell to come loose. It can then be peeled away and deposited

onto another material. The researchers demonstrated that the

efficiency of the solar cell wasn't affected by the transfer process.

The current paper shows that

the process works for dislodging a solar cell from a silicon and silicon

dioxide wafer. Zheng says the group has also demonstrated the process

with solar cells made on a glass surface, but this work has not yet

been published. This could make it possible to use the technique with

copper indium gallium selenide solar cells, which are nearly twice as

efficient as amorphous ones.

|

4) Review of

US DRIVE Partnership

|

|

Lorin Hancock,

Jan. 23, 2013, National Academy of Sciences

(Ed. Note:

scroll down to Amory Lovins' solution to a complex political problem

cited in this press release! - TV)

FOR IMMEDIATE

RELEASE

WASHINGTON -- A new report from

the National Research Council calls the operation and management of

the technical teams of U.S. DRIVE generally "exemplary,"

but finds that its Executive Steering Group has not provided adequate

guidance for fitting the technical teams' work into an overall plan

for the partnership's goals

of reduced petroleum use. The public-private partnership

has made steady progress in creating viable alternatives to

gas-powered vehicles, but formidable

technical barriers have

prevented the emergence of a stand-out contender to replace petroleum.

U.S. DRIVE is a

government-industry partnership conducting precompetitive research

and development to help accelerate the emergence of advanced

technologies for clean and efficient light-duty vehicles that could

eventually compete commercially with petroleum vehicles. The

partnership participants include four automotive companies, five

energy companies, two electric power companies, and the Electric

Power Research Institute, with the U.S. Department of Energy

providing federal leadership. The partnership has determined

three potential primary pathways

to reaching significantly reduced petroleum consumption: improved

internal combustion engine vehicles coupled with greater use of

biofuels and natural gas in conventional or hybrid vehicles; expanded

use of plug-in hybrid electric vehicles and battery electric vehicles;

and the possible transition to hydrogen as a transportation

fuel. Nine technical teams, including those on hydrogen

storage, grid interaction, and combustion and emissions control,

focus on specific research needed to make any or all of the pathways a

commercial possibility.

As in previous

Research Council reviews of the FreedomCAR and Fuel Partnership --

predecessor of U.S. DRIVE -- the report finds the operation and

management of the technical teams and the integration of the systems

analysis functions within those teams to be exemplary for the most

part, and provides recommendations in specific technical areas.

However, it is not apparent that critical issues being investigated

by the technical teams are guided and prioritized by an overall understanding

of how these technical improvements affect larger program

goals. Without overarching guidance, there is a potential for

conflict among the respective goals of the various technical

teams. It is imperative that the partnership's Executive

Steering Group, Joint Operations Group, or other program

decision-making groups continually broaden their understanding of

these implications and adapt research plans to provide effective

portfolio management.

The Executive

Steering Group should set targets for the technical teams that are

consistent with the objectives of reduced

petroleum consumption and greenhouse gas emissions,

and U.S. DRIVE should conduct a comprehensive review of the

partnership's portfolio, the report says. Focusing on the

mission of supporting longer-term, higher-risk precompetitive

activities in all three potential primary pathways, the review will

ensure that research and development efforts are adequate and

appropriate to achieve the targets. The report also recommends

adopting a portfolio-based research and development strategy to

balance the investment among alternative pathways with more

traditional reviews of the individual pathways' progress.

The

study was sponsored by the U.S. Department of Energy. The

National Academy of Sciences, National Academy of Engineering,

Institute of Medicine, and National Research Council make up the

National Academies. They are private, independent nonprofit

institutions that provide science, technology, and health policy

advice under a congressional charter. The Research Council is

the principal operating agency of the National Academy of Sciences

and the National Academy of Engineering.

RELATED

COMMENTARY AND SOLUTION

From: On

Behalf Of Amory

B. Lovins

Sent: Wednesday,

January 23, 2013 2:29 PM

To: Global

Energy Network

Subject: Re:

[global-energy] FW: New Report: Review of U.S. DRIVE Partnership

The problems referred

to have a common cause and a common solution. They can be resolved by

a different vehicle-design strategy starting with platform

"fitness" - taking the obesity (unnecessary weight and

drag) out of the automobile. This not only saves about two-thirds of

the tractive load (the energy required to move the auto), at

approximately zero net marginal manufacturing cost, but also makes

affordable the advanced powertrains, specifically electrification,

that can displace the rest of the fuel. This strategy is described in

Chapter Two of Reinventing

Fire (www.reinventingfire.com,

2011). It confers strong competitive advantage on early adopters; is

already being adopted by some automakers, often with RMI's help, and

is in discussion with others; and has been encouragingly received by

DOE leadership.

Amory B. Lovins

Chairman and Chief Scientist

Rocky Mountain Institute

1739 Snowmass Creek Road

Snowmass CO 81654, USA

ablovins@rmi.org

back to table of contents

|

5) Lithium-sulfide

Batteries could store far more Energy than Lithium-ion

|

Kevin Bullis,

Technology Review, January 2013

http://www.technologyreview.com/news/508466/two-advances-point-toward-a-cheaper-electric-car-battery/?utm_campaign=newsletters&utm_source=newsletter-weekly-energy&utm_medium=email&utm_content=20121224

For the

roads to start filling up with electric cars, batteries will need to

get much cheaper-as much as 80 percent cheaper by some estimates (see

"How Improved

Batteries Will Make Electric Vehicles Competitive").

Two recent advances that make an experimental type of battery much

more practical could lead to such cost savings.

Researchers

have for years been working on a type of battery that uses lithium

metal in one electrode and sulfur in the other. In theory, this kind

of battery could store three to five times as much energy as a

conventional lithium-ion battery (see "Revisiting

Lithium-Sulfur Batteries"). But lithium metal is

highly reactive when exposed to water and can form root-like

structures inside batteries over time; these structures can join

positive and negative electrodes, causing short circuits and even

fires. So many researchers have begun turning their attention to a

similar battery that doesn't require lithium metal.

In the new type of battery, the sulfur

electrode is replaced with a lithium-sulfide material-a compound that

contains both lithium and sulfur. This becomes the source of the

lithium, so the lithium metal is no longer required and can be

replaced with graphite-a material used in lithium-ion batteries

today-or with a material such as silicon.

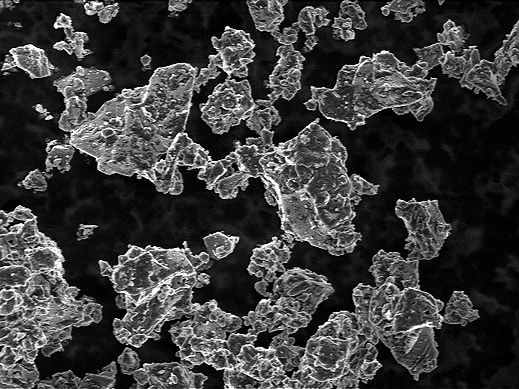

The trouble is, lithium sulfide is electrically

insulating, which slows down charging and reduces the amount of

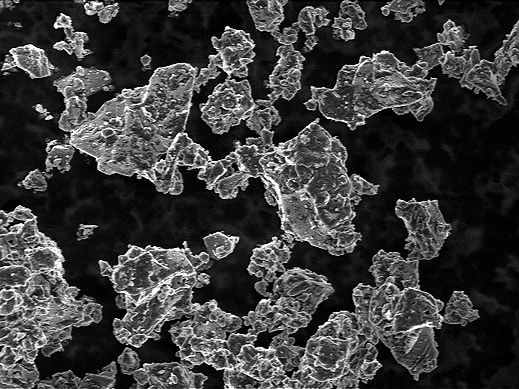

energy the battery can deliver. But two recent papers, one from

Stanford and the other from Lawrence Berkeley National Laboratory,

offer ways to make lithium-sulfide batteries more practical.

These

research papers demonstrate low-cost methods for making

lithium-sulfide batteries with high-energy storage capacities. The

work could lead to commercial batteries that store more than three

times as much energy as the lithium-ion batteries currently used in

electric vehicles, says Yuegang Zhang,

a staff scientist at Lawrence Berkeley National Laboratory.

Earlier this year, Yi Cui, a materials science

professor at Stanford, showed a way to overcome the inherent

limitations of lithium-sulfide batteries by charging the battery at a

higher voltage than usual for its first charge. This changes the

chemistry of the electrode, getting around the conductivity problem.

Even then, the lithium sulfide had to be mixed

with carbon to improve its conductivity, and the carbon decreases the

amount of energy the electrode can store: in experiments, it was

enough to reduce the battery's capacities to levels close to

conventional lithium-ion batteries.

Zhang demonstrated a new way to mix the carbon

with the lithium sulfide that greatly reduces the amount of carbon needed

in the cathode. The percent of the electrode that's made up of

lithium sulfide increases from less than 50 percent to 67.5 percent.

This improvement, in part because it's amplified by improvements it

allows in other parts of the battery, could nearly double the overall

battery storage capacity, from 350 to 610 watt-hours per kilogram,

Zhang estimates. (Lithium-ion batteries in electric vehicles now

typically store less than 200 watt-hours per kilogram.)

Obstacles remain to commercializing the technology,

including the need to improve the number of times the batteries can

be recharged and the speed with which they can be charged. The energy

storage numbers should also be taken with a grain of salt-they're

estimates derived from lab-scale experiments, not measurements of

large, commercial-scale batteries.

And

lithium-sulfur batteries that use lithium metal may yet prove to be

the technology of choice. Researchers and companies such as Sion

Power and Polyplus are making progress on improving the number of

times they can be recharged, and are using ceramics or other

materials to address safety issues (see "Beyond Lithium Ion:

ARPA-E Places Bets on Novel Energy Storage").

|

About Integrity Research Institute

Future Energy eNews is

provided as a public service from Integrity Research Institute,

a Non-Profit dedicated to educating the public on eco-friendly

emerging energy technologies.

FREE copy

of the 30 minute DVD "Progress in Future Energy" is

available by sending an email with

"Free DVD" in subject and mailing address in

body.

Your generous support is

welcome by making a tax deductible donation on

our secure website

|

|

|

|

- Scott Kelsey, Missouri State, explaining Rejuvamatrix, Pulsed EMF

therapy to increase the length of DNA telomeres, which directly

affect our lifespan.

- Max Formitchev-Zamilov, Penn State, discussing Cavitation Induced

Fusion, that will soon provide power generation and heat

production.

- Christopher Provaditis, from Greece, explaining Inertial

Propulsion and who teamed up recently with Boeing for their space

satellites.

- PJ Piper of QM Power, discussing the motor invented by

Charles Flynn, with a revolutionary parallel path that gives

double and triple efficiency.

- Dr Thorsten Ludwig from Germany (GASE) discussing

the mysterious Hans Coler motor that WWII British Intelligence

researched.

|

|

|

|

|

|